From one-off to a thousand off-

Our engineering facilities include most of the traditional (no CNC at present) metalworking processes normally found in small engineering companies plus a couple that are maybe less common:-

Drilling & Tapping

Bench/pillar drills including an articulated arm machine with a maximum throat of 2ft./60cm.- capable of drilling a 23mm hole in the middle of something 4ft./120cm wide.Larger holes can be bored out.

Auto-reversing tapping attatchments for the above.

Special purpose air operated drilling machines.

Grinding and linishing

Grinders mostly used for our own toolmaking & sharpening requirements.

Various vertical & horizontal linishers and band grinders for de-burring and surface finishing - often used for pre-polishing operations.

Lapping

24” Flat Lapping Machine - parts to be lapped must fit inside 9.75”(247mm) dia. rings.

Milling

Horizontal,Vertical & Turret Milling machines

Presswork/Sheetmetalwork

Various Fly Presses up to no.6A (12”/305mm deep throat)

6 ton power press.

Small guillotine,Shears,Folders

Sawing

Cut-off Saws,Bandsaws

Slotting

Slotting attatchment on milling machine

Turning

Conventional & Capstan Lathes up to 17”swing x 50” between centres (430mm x 1270mm)

Parts made using the above processes can also be welded together and/or polished if required and we can also handle plating or anodising.

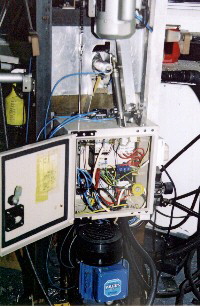

Rear view (showing control box,motors,etc.)of purpose made electrically powered,pneumatically operated,automatic drilling,de-burring,reaming and spot-facing machine designed and built in-house.

Press Tool

for punching multiple holes.